PETG Data Sheet, Description & Applications

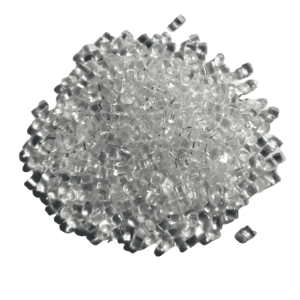

Polyethylene Terephthalate Glycol, known as PETG or PET-G, is a thermoplastic polyester that delivers significant durability, chemical resistance, and formability for manufacturing. PETG is an adaptation of PET (Polyethylene terephthalate), where the ‘G’ stands for Glycol. In addition, it is added at a molecular level to offer different chemical properties. Furthermore, PET uses the same monomers as the glycol-modified PETG. Thus, PETG has greater strength and durability. PETG has more impact resistant and is better suited to higher temperatures.

On the one hand, compared to other plastics, PETG has significant chemical and heat resistance, good durability, and formability. Thanks to its flexibility, this material is suitable for applications that require impact resistance. As we mentioned above, PETG is food-safe and non-toxic.

On the other hand, since PETG has a softer surface than PET, it’s more prone to wear. That being said, it remains more durable and heat resistant than PLA.

PETG Applications

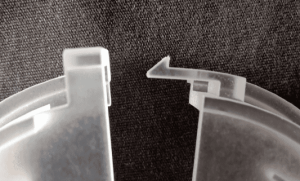

In the 3D printing industry, PETG is typically used in models that need high resistance or some flexibility, like snap-fit components.

Retail Stands and Displays

PETG is a material used in brick and mortar and point of sale retail stands and displays. Since it can be colored, PETG is also ideal for signage.

Food and Drink Containers

Since PETG doesn’t deteriorate with water, it is the most suitable material for food-related prints.

PETG isn’t a toxic substance and is FDA-approved.

3D Printing

Polyethylene terephthalate glycol has gained massive popularity for its ease of use in modern 3D printers. PETG filament prints easily and provides excellent layer adhesion. Low shrinkage rates allow for larger prints than with PLA or ABS, while PETG is also strong, chemical resistant, and odorless while printing.

It is advised that a cooling fan is used while printing with PETG, while problems with printing bed adhesion can be overcome by putting down a layer on the build plate.

PETG Data Sheet

PETG Data sheet downloadable available here.

Product Name: PETG Co-polyester Polyethylene Terephthalate Amorphous Resin

Date of issue: 4/10/2022

1. Identification of the Company and the Substance/Preparation

Trade name: IIID MAX PETG 3D Printing Filament

Use of the product: Biodegradable resin for 3D printing

Description: PETG / PET-G or Polyethylene Terephthalate Glycol, is a thermoplastic polyester that provides significant chemical resistance, durability, and excellent formability for manufacturing. PETG can be easily vacuumed and pressure-formed as well as heat-bent thanks to its low forming temperatures

Manufacturer: IIID MAX, 11701 NW 102nd Rd, Suite 10, Medley, FL 33178

2. Hazards identification

Classification: Not dangerous. The fumes are not toxic, but it’s always best to ventilate your printing room properly. There are some carbon emissions from the fumes when printing with PETG, but experts have concluded that they pose no significant health risks.

Special advice on hazards: May form combustible dust concentrations in air

3. Composition/information on ingredients

Chemical characteristics: Co-polyester Polyethylene Terephthalate

Additional information: The polymer contains minor additives such as stabilizers and catalysts. These additives are immobilized by the polymer and are not released with normal use.

4. First-aid measures

On skin contact: In case of contact with the hot polymer, apply cold water immediately. Ensure that you have medical aid substances in case you have to remove adhering material and for taking care of burns.

After inhalation: Remove yourself out of the inhalation zone, and find fresh air. In case of discomfort, call a physician.

On ingestion: Make sure to rinse your mouth with water. No effects are known. Contact a doctor in case of discomfort.

On eyes contact: Rinse open eyes thoroughly with water.

5. Fire-fighting measures

Suitable fire extinguishing: Carbon dioxide, water, and dry chemical extinguisher.

Special exposure hazards: Product may form explosive dust-air mixtures if a high concentration of product dust is suspended in the air.

Special protective equipment: Self-contained breathing apparatus, masks, and gloves

Remark: The accumulations of dust can be inflammable.

6. Environmental Information

Biological degradation: Biodegradation and bioaccumulation are unlikely events due to the size of these polymers. While the ester exchange linkage of the polymers has the potential to hydrolyze, their insolubility is expected to prevent significant breakdown under environmental conditions.

Ecological effects: Based on their high molecular weight and insolubility, the acute L50 values for aquatic species are expected to be >100 mg/L and >10 mg/L for chronic toxicity.

7. Storage

Storage: Having solutions to store your PETG is essential to avoid humidity and dust. Store cool and keep packaging closed when not in use. Avoid sources of ignition. Store in the original container in a dry, cool, and well-ventilated area, away from flame, and ignition sources. Also, avoid direct sunlight or incompatible materials. Maintain good housekeeping to control dust accumulations.

If your final part should withstand force or torque, your PETG filaments need to be dried. if the relative humidity is around 30% or less, there is no need to dry PETG.

8. Exposure controls & personal protection

Occupational exposure limits:

OSHA (PEL): 15 mg/m3, 8 Hr. TWA (total dust) – 5 mg/m3, 8 Hr. TWA (respirable fraction) as particulates not otherwise classified (PNOC)

ACGIH (TLV): 10 mg/m3, 8 Hr. TWA (inhalable particles, recommended) – 3 mg/m3, 8 Hr. TWA (respirable particles, recommended)

Personal Protection: Avoid eating or drinking during working closely with your printers. Also, avoid contact with hot material on your skin. Avoid inhaling dust and vapors.

9. Physical and chemical properties

Filament Diameter: 1.75mm

Print Speed: 20~100 mm/s

Print Temp:230°C – 260°C

Heated Bed Temp:70℃ – 90℃

Precision: +/- 0,05mm

Recommended Storage Temperature : -20 to 50 °C / -4 to 122 °F

Empty Spool: 0.2 kg

Full Spool: 1.2 kg

Dimensions: 8.5 × 8.5 × 3 in

10. Regulatory Information in the USA

This document has been prepared in accordance with the SDS requirements of the OSHA Hazard Communication Standard 29 CFR 1910.1200. OSHA Classification: Non-hazardous

Under RCRA, it is the responsibility of the product user to determine at the time of disposal whether a material containing the product or derived from the product should be classified as Hazardous waste (40 CFR 261.20-24).

If discarded in its purchased form, this product does not meet the RCRA characteristic definition for ignitability, corrosivity, or reactivity and is not an RCRA-listed waste; however, it has not been tested by the Toxicity Characteristic Leaching Procedure (TCLP).

SARA, Title III: This material is not known to contain extremely hazardous substances.

Copyright © 2022 by IIID MAX